Externally Variable Compressors are being used in more and more vehicles. The Critical difference in these compressors is in that they run continuously when the engine is running and have their output varied from external inputs by varying the degree of offset on the swash plate. This change of design is significant and additional precautions need to be observed when handling and servicing systems with this type of compressor.

Handling Precautions

This type of compressor should not be handled by the Pulley and are also sensitive to being knocked or dropped. Greater care must be taken when handling these compressors especially the pulley as it is not a serviceable part and if broken requires replacement of the complete compressor.

Do Not Start Engines without Gassing

Do not start the vehicle without first charging the system with the correct amount of refrigerant. If the vehicle must be moved all of the following conditions must be met.

* The A/C must be switched off

* Engine RPM must be kept as low as possible and not to exceed 2000RPM

* Maximum running time is 15 Minutes

Run In Requirements

After charging the A/C system with refrigerant to the specified amount Run-in the compressor as follows:

* Start the engine and allow to idle at less than 1500RPM

* Turn A/C switch on

* Adjust Temperature control to Max cold

* Turn Fan speed to High

* Idle Engine for at least 2 minutes

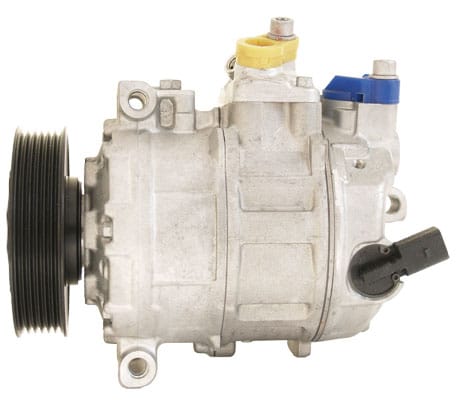

These Compressors can generally be recognised by lack of magnetic coil and wiring behind the front hub and the control connection at the rear as the A09-9411GQ below has.

Information kindly supplied by Denso Service.

A09-9411GQ