Or - when can I flush and when is it not possible or wise to flush a Condenser? Firstly it is important to know why and when a Condenser may need flushing or replacing if flushing is not possible without potentially causing future damage to the system.

Firstly it is important to know why and when a Condenser may need flushing or replacing if flushing is not possible without potentially causing future damage to the system.

The only moving parts in the refrigerant system prone to wear are the internals of the Compressor. The Compressor is completely subject to many possible adverse conditions within the system that can very quickly cause permanent and catastrophic damage to it that will in turn contaminate the whole refrigerant circuit.

Some of these are:

- Over-gassing particularly an issue with modern systems which can hold much less refrigerant than older systems. Refer Tech Tip - Critical Refrigerant charge rates.

- Running low on refrigerant with resultant poor lubrication

- Lack of oil, Refer to Tech Tip 7 on oil balancing.

- Poor Condensing due to an externally blocked Condenser or faulty Condenser fan.

- Lack of servicing and moisture contamination causing acid like build up in the system causing damage.

- Improper recharging – very possible with vane type compressors – care must always be taken to not introduce liquid in any form to an operating system.

- Over oiling or adding too much dye to a system.

- Damaged lines causing lack of flow back to the compressor.

- Liquid flood-back due to over gassing, lack of evaporator efficiency due to debris blocking the Evaporator (leaves, tissues etc.) or a faulty TX valve allowing too much flow.

Any of the above conditions can lead to compressor failure and particle contamination of the rest of the system. The Condenser is the first in line to be contaminated and you would think that the Receiver Drier/Filter would protect the new compressor from damage by filtering the refrigerant passing through it but the damage is often caused the first time the new compressor turns off and the high pressure created in the Condenser (when the compressor shuts down and the system equalises), caries contaminates back to the compressor.

This then contaminates the new compressor with the resulting failure the next time it is run.

Older single pass Condensers could be successfully flushed as when you had good flow of flush through the system you know it is going through the whole system. Multi-pass Condensers on the other hand cannot be successfully flushed as much like a radiator, when pressure and a flushing agent is applied it will take the easiest path of least resistance and not until the system is put back into operation when the resultant high flow/high pressure allows the contaminating particles to loosen and cause the condition described above.

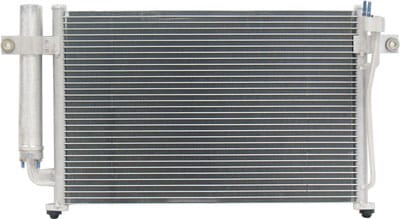

Alcius A07-7142

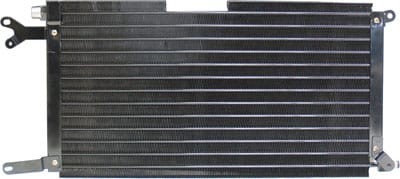

Alcius A07-7003

Single pass condenser cross section

Cross-section of a “Modine” single pass condenser. This type of condenser is single pass with quite small tubes internally in some cases thorough flushing will clean successfully .

The only safe option is to check what type of condenser is fitted when a contaminated compressor is replaced and quote to also change the Condenser, TX Valve and Drier along with a complete system flush.