OUTLINE

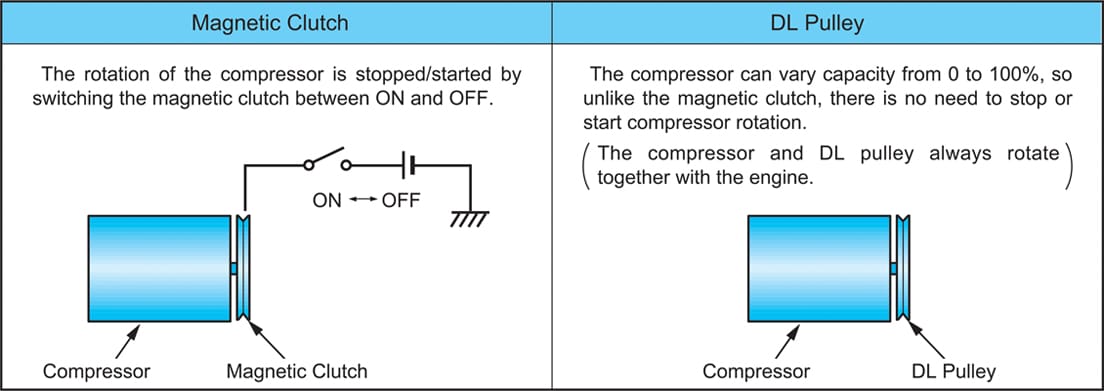

Recently, continuously variable capacity (from 0 to 100%) compressors have started to be used in order to improve fuel consumption, power consumption, acceleration performance and to reduce ON/OFF shock. Because the capacity is varied continuously, there is no need for a stop/ start mechanism for the magnetic clutch between the engine and compressor.

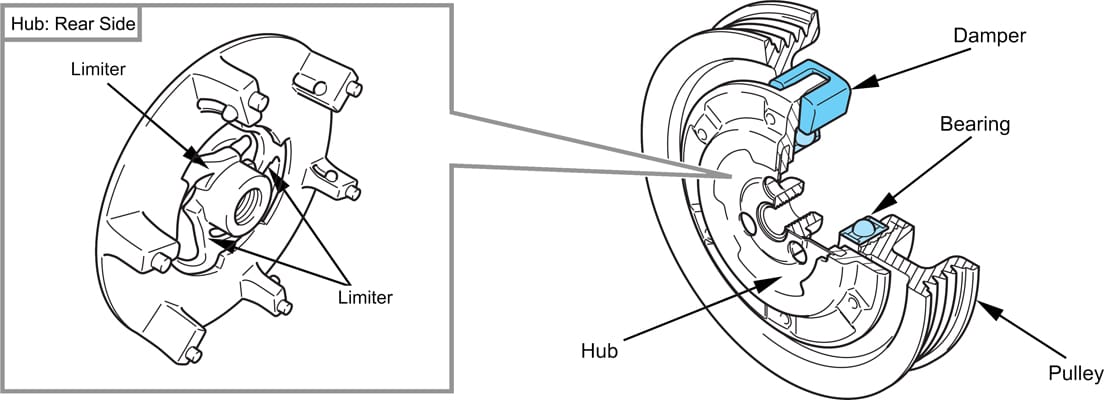

However, a damper is needed to absorb variations in the compressor torque, and a limiter is needed to protect the belt should the compressor lock. The use of DL (Damper & Limiter) pulleys that include these functions has increased recently. This section describes the DL pulley, including precautions required when replacing the compressor.