Mostly Found in Denso applications are Slip Sensors that are designed to alert the vehicle driver and shut down the compressor if a drive belt slipping issue is detected.

Compressors that are fitted with a slip sensor produce an RPM related signal, the vehicle has an ECU that compares this signal therefore the rpm of the compressor to the engine rpm. As the ratio between these rpm’s should remain constant, any variation will indicate a difference in the ratio of speed between the compressor and engine and this will generally mean either one of 2 things.

1. The Compressor Drive Belt is slipping The drive belt is slipping due to a number of reasons, old worn or glazed belt or high head pressure being two. The belt issue is easily overcome by fitting and correctly tensioning a new belt and ensuring the pulley does not have any debris limiting the belts ability to grip. High head pressure is more of a problem as this can be due to a number of factors, poor condensing, due to externally blocked condenser, condenser fan, either engine or electrically driven not operating or operating poorly or over-gassing being just a couple of reasons.

2. The Compressor Clutch is slipping Again the common issue here is high head pressure as described above or a compressor that is in the process of seizing due to any number of causes, lack of lubrication and lack of refrigerant to cool the compressor and carry lubricant again just two reasons. Lack of Voltage should also not be discounted, much like any electrical device the clutch coil requires the correct supply voltage to operate correctly. The Air Gap of the clutch also needs to be correct, this is unlikely to change due to wear of the clutch plates if correct voltage is supplied.

If any of these situations are detected most vehicles fitted with a slip sensor type compressor will, shut down the compressor and/or alert the driver with a warning light on the dash. This is designed to protect the belt so it can continue to drive other accessories that depend on it and/or avoid further damage to the compressor.

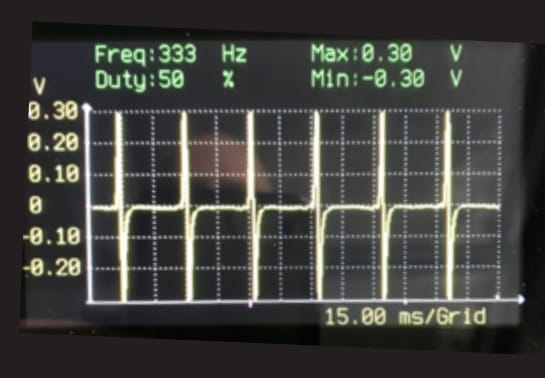

Fig. 1

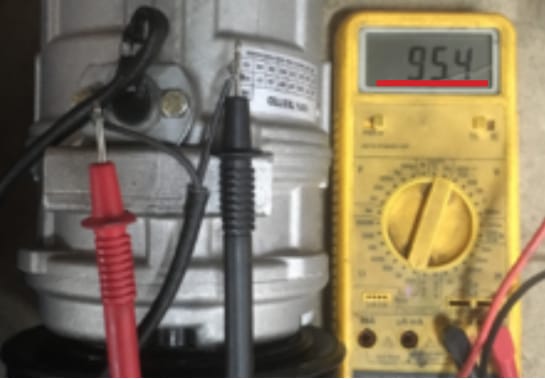

Fig. 2

Fig. 3

Fig. 4